INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

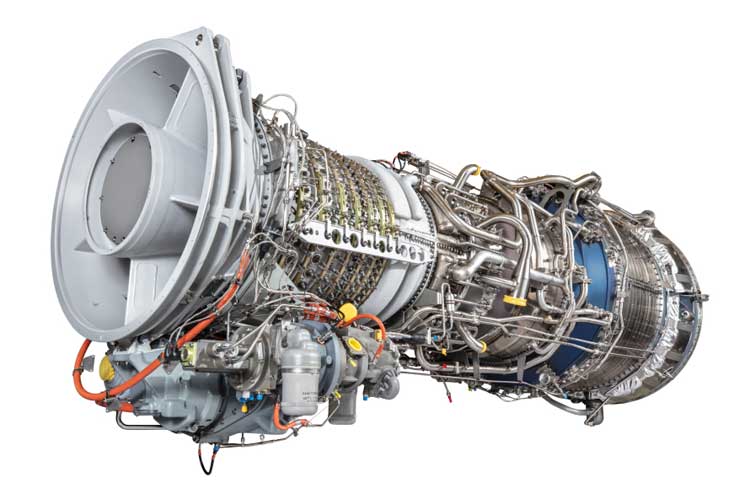

GE Aerospace's Indian supply chain grows to 13 companies

GE Aerospace's 'Make in India' strategy has helped increase local sourcing spend by 20 times in five years

As it prepares to participate in India's DefExpo this week, GE Aerospace announced its Indian aero-engine supply chain has grown to 13 companies plus GE's Pune multi-modal manufacturing facility.

Indian companies are becoming globally competitive for a growing body of high-value, complex aero-engine manufacturing work. Marquee Indian companies including Tata Advanced Systems, Mahindra Aerostructure and Godrej have set up GE aero-engine component production lines. These components are exported from India to GE's engine manufacturing facilities. Hindustan Aeronautics has established an assembly line for GE's LM2500 marine engine that power India's newest first indigenous aircraft carrier, the Vikrant. These growing capabilities coincided with GE Aerospace's increase in local sourcing spend, which has grown 20 times in the last five years.

GE Aerospace and its Indian partners are in the process of establishing the aero-engine manufacturing infrastructure India needs to achieve its self-reliance goals (locally known as 'Aatmanirbhar Bharat'). "Indian companies have a keen willingness to partner with GE Aerospace and to join the aero-engine marketplace. They have demonstrated the ability to master the complex manufacturing and special processes required for aero-engine manufacturing while simultaneously maintaining focus on quality," said Youngje Kim, Vice President, Sales for Asia at GE's military aviation division.

To support its growing Indian aero-engine manufacturing industrial base, GE Aerospace is pursuing an aggressive skill development program for manufacturing workforce in India. Over the past two years, this GE-funded program trained more than 150 manufacturing staff at the various partner organizations, and these trained workers have then gained employment with one of several GE suppliers in India. "GE's Indian skill development program when combined with our growing Indian industrial base is a testament to our support of Make in India," added Kim.

More than 1000 of GE's aviation researchers and engineers work in India and have deep connections with leading academic institutions, such as IIT-Madras, IIT-Kapur and IIT-Patna.

GE's aviation footprint in India includes military aviation equipment, commercial aviation engines, marine operations, avionics, maintenance, product development and research in addition to local manufacturing. GE's supply chain partners in India include

- Tata Advanced Systems Ltd.

- Tata Advanced Materials Ltd.

- HAL Foundry & Forge

- Mahindra Aerostructures Pvt. Ltd.

- Godrej & Boyce Mfg. Ltd.

- Tata Sikorsky Aerospace LTd.

- zad Engineering

- Raghu Vamsi Pvt. Ltd.

- Ankit Aerospace Pvt. Ltd.

- Sundaram Fasteners

- IndoMIM Tec Pvt. Ltd.

- Maini Precision Products Pvt. Ltd.

- Recaero