INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- A leap in Indian aviation: Prime Minister Modi inaugurates Safran's Global MRO Hub in Hyderabad, Calls It a Milestone

- All about HAMMER Smart Precision Guided Weapon in India — “BEL-Safran Collaboration”

- India, Germany deepen defence ties as High Defence Committee charts ambitious plan

- True strategic autonomy will come only when our code is as indigenous as our hardware: Rajnath Singh

- EXCLUSIVE: Manish Kumar Jha speaks with Air Marshal Ashutosh Dixit, Chief of Integrated Defence Staff (CISC) at Headquarters, Integrated Defence Staff (IDS)

- Experts Speak: G20 Summit: A Sign of Global Fracture

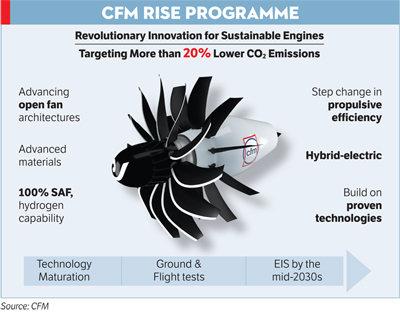

CFM RISE — Full Speed Ahead!

Three years into the programme, it is clear that various RISE technologies are steadily evolving from promising design concepts to functioning components and systems. And the pace of progress is accelerating.

There is a growing realisation in the aviation industry that it cannot possibly reach its net zero carbon emissions goal by 2050 by banking solely on sustainable aviation fuel (SAF) and incremental improvements in fuel efficiency. Revolutionary new engine designs and cutting-edge technologies are essential. And CFM International, a 50-50 joint venture between two of the world’s leading aerospace companies – General Electric Aerospace (GE) and Safran Aircraft Engines (SAE) – has always been in the forefront of engine design and technological innovation.

CFM’s very first product, the CFM56, was a high-bypass turbofan engine that entered service in 1982, and brought a significant jump in fuel efficiency over other jet engines of the era. It eventually became the most successful commercial aviation engine in history. Not content to rest on its laurels, CFM introduced the LEAP engine in 2016. Over the past eight years LEAP has done exceedingly well, delivering 15 to 20 per cent better fuel efficiency than the CFM56-5B and CFM56-7B engines. In sales, it has left the competition far behind.

In fact, CFM’s engines are the primary choice of single-aisle aircraft operators around the world. Currently CFM has about 39 per cent market share, which makes it the largest commercial aircraft engine manufacturer in the world. But with climate change taking centre stage in practically every major forum, another step change in aero engine efficiency is urgently required. Enter the CFM RISE programme.

RISE’S BUILDING BLOCKS

The CFM International RISE (Revolutionary Innovation for Sustainable Engines) Technology Demonstration Programme was launched on June 14, 2021. Its goals include reducing fuel consumption and carbon emissions by more than 20 per cent compared to today’s most efficient engines, as well as ensuring compatibility with alternative energy sources like SAF, electricity and hydrogen. It incorporates several technological innovations aimed at improving the efficiency, performance, and sustainability of aircraft engines. The 35,000lb (156kN)-thrust class RISE programme will allow CFM to mature the technologies required for a new single-aisle engine to potentially enter service in the mid-2030s.

RISE’s main features include:

- Open Fan: RISE features an innovative 13-foot-diameter open fan which will enable a much higher bypass ratio and probably bring the single greatest engine efficiency increase that CFM has ever achieved. While noise is an inherent drawback of the open fan architecture, RISE incorporates several measures to reduce noise levels to below the permissible value.

- Compact high-pressure core: A high-power gear system and a new compact high-pressure (HP) core will boost thermodynamic efficiency.

- Sustainable Aviation: RISE will be more environmentally friendly than other engines by improving fuel efficiency, reducing carbon emissions, and minimising noise pollution. Compatibility with alternative fuels is a key requirement.

- Advanced Materials: RISE integrates cutting-edge technologies such as ceramic matrix composites (CMCs), 3D printing, and advanced manufacturing techniques to enhance engine performance and efficiency. Composite blades are GE’s forte. Having introduced composite fan blade technology commercially with the GE90 engine back in 1995, GE has totalled more than 100 million engine flight hours with such blades.

- Hybrid-Electric Propulsion: The RISE programme is exploring the integration of hybrid-electric propulsion systems with single-aisle engines, aiming to further reduce emissions and fuel consumption.

- Real-time Engine Monitoring: Performance optimisation and predictive maintenance, including advanced engine health monitoring systems and data analytics capabilities will be inbuilt so as to extract the maximum possible advantage from the engine.

- Commercialisation: The ultimate goal of the RISE programme is to develop engines that meet all regulatory certification requirements and are ready for commercial exploitation.

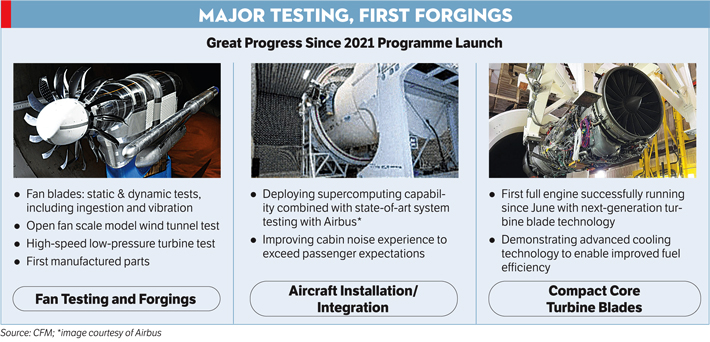

TESTING TIMES

With more than 1,000 engineers deployed on the CFM RISE, the programme is supported by CFM’s most comprehensive testing roadmap yet. Work is progressing simultaneously on multiple fronts.

- In January 2024, SAE announced that wind-tunnel tests of the scaled ECOENGInE had begun at facilities run by French aerospace research agency ONERA. The tests are to support the maturation of the open-fan’s aerodynamic and acoustic performance. Ingestion tests have already been performed on open rotor fan blades. According to SAE’s Pierre Cottenceau, around two-thirds of the planned 200h of testing have been completed. He added, “I would say generally we are very happy with the test results.... (which) have come out a bit better than predictions.” The first full open fan demonstrator engine is expected to start ground testing in 2025-26, with another pair of engines due to start flight testing around two years later with Airbus.

- Earlier, in 2023, to simulate air movement of a full-scale open fan design in intricate detail, GE Aerospace created special computational fluid dynamics software and ran it on Frontier, the supercomputer of the US Department of Energy’s Oak Ridge National Laboratory. Frontier is the world’s fastest supercomputer and can make more than a quintillion calculations per second.

- Acoustic performance is crucial during cruise conditions, in which low cabin noise is the primary goal. CFM claims that it has made significant progress in acoustics, and that the open fan noise levels are already on the lower end required for certification.

- Tests on RISE’s next-generation high-pressure turbine, which were recently conducted at GE headquarters in Evendale, Ohio, confirmed that it can deliver significant fuel efficiency improvements and increased durability. The technology will be useful in the compact core GE Aerospace is developing for the RISE programme through NASA’s Hybrid Thermally Efficient Core (HyTEC) programme, which has so far focused on high-pressure compressor and high-pressure turbine advanced aerodynamics, along with work on the combustor. However, to shrink the size of the core while maintaining the same level of thrust, both heat and pressure must increase compared to conventional jet engines. This means the engine core must be made of more durable composite materials that can withstand higher temperatures. The CMC parts that GE has developed over the past decade are one-third the weight of steel but can withstand temperatures as high as 1,300 degrees Celsius, which is beyond the melting point of many advanced metallic superalloys.

- Tests have been conducted at NASA’s Electric Aircraft Testbed facility in Sandusky, Ohio, as part of NASA’s Electrified Powertrain Flight Demonstration (EPFD) project. These tests have validated GE’s hybrid-electric propulsion system architecture approach and cleared the way for further tests of a mildly hybridised turbofan as part of the RISE programme. In 2022, working with NASA, GE was the first to test a multi-kilovolt, megawatt-class hybrid electric power system in conditions simulating altitudes up to 45,000 feet.

- RISE technologies are being developed for compatibility with alternative energy sources as well, especially with 100 per cent SAF. SAF is generally acknowledged as the industry’s brightest hope to cut emissions and achieve net zero by 2050.

- Around 2026, Airbus and CFM plan to flight-test a GE Passport engine modified for direct combustion of hydrogen fuel. The tests form part of the RISE effort and are intended to prove technology for entry-into-service of the first of several generations of Airbus zero-emission aircraft by 2035.

INNOVATION EVERYWHERE

Overall, CFM has already been able to reduce the complexity, weight and noise level of the RISE engine while maintaining significant performance benefits. In particular, the open fan design is now simpler and lighter. Stationary outlet guide vanes will replace previous two-stage, counter-rotating fan blades in the new architecture. This innovative change is crucial because it permits flight at speeds comparable to conventional turbofan engines.

With single-aisle planes constituting almost 70 per cent of the world’s rapidly growing commercial aviation fleet, the need to develop more efficient engines to power these aircraft is growing. For once, it is not fuel prices that are driving innovation. Rather, it is the need to reduce CO2 emissions to achieve a more sustainable aviation industry.

Once RISE emerges as a finished commercial product, the existing airframes will not serve. That is why CFM is maintaining close liaison with Airbus and Boeing seeking to convince them that RISE will definitely emerge as an amazing engine that will deliver a fuelburn reduction of over 20 per cent. Otherwise neither company is likely to gamble on risky new technology. In fact, Boeing, may be more inclined to pursue its Transonic Truss-Based Wing (TTBW) – a long and highly flexible slender wing, braced by trusses that also generate lift. Together with greater use of composite materials and other cutting-edge technologies Boeing believes the TTBW could deliver over 20 per cent fuel efficiency gains.

However, according to Mohamed Ali, Vice President of engineering for GE Aerospace, the 20 per cent efficiency goal “is practically impossible.... without the open fan”. His irrefutable logic is that a current turbofan could be 20 per cent more efficient only if its core burned at “half the temperature of the sun’s surface.” “There is no material on earth that can sustain that,” he sums up.

Three years into the programme, it is clear that various RISE technologies are steadily evolving from promising design concepts to functioning components and systems. And the pace of progress is accelerating. According to Arjan Hegeman, general manager of Advanced Technology at GE Aerospace, “It’s full speed ahead for the RISE programme in 2024.”