INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

Flight to the Future

The speedy induction of extremely capable American aircraft for the IAF’s transport fleet should not give rise to complacency because the nation needs to have its own manufacturing expertise

In the last decade, the transport fleet of the Indian Air Force (IAF) was in deep distress. The heavy-lift Ilyushin Il-76MD four-engine jets were being grossly over-utilised and fast running out of spares, the medium-lift Antonov An-32 twin turboprops were finishing their nominal 25-year technical life and the Hindustan Aeronautics Limited (HAL) HS 748M Avro twin turboprops were breaking every record for longevity of service with no replacements in sight. Consequently half or less of the aircraft on strength were making it to the flight line each morning. And with the nation keen to shoulder greater responsibilities in the region and beyond, the demands on the air transport fleet were growing. In short, the situation was turning critical and desperate.

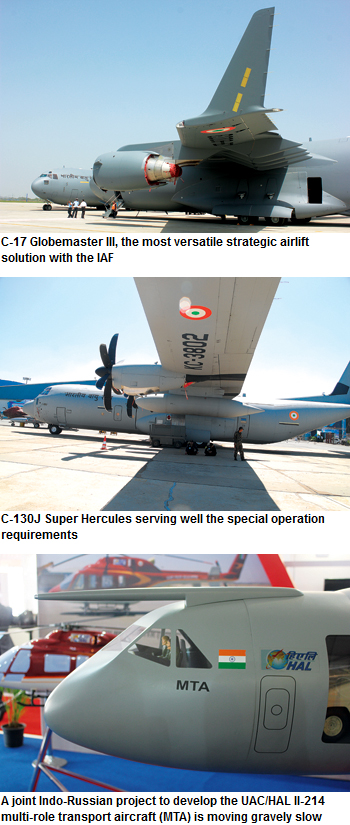

Things began to improve in 2008 with the induction of Lockheed Martin C-130J Super Hercules and Boeing C-17 Globemaster III aircraft from the United States. There was further progress as the An-32 fleet was earmarked for midlife upgrade and the long-awaited Avro replacement deal was cleared. The casual observer, therefore, may get the impression that the IAF transport fleet is in fine fettle. However, the fleet could again fall on hard times 20 years from now.

Heavy-Lift Happiness

In 2011, the Indian Government signed a $4.1-billion deal for the purchase of 10 Boeing C-17 strategic airlift aircraft through the US Government’s foreign military sales (FMS) programme. This marked a step change in the capability of the IAF’s transport fleet because the C-17’s 74.8-tonne payload capacity was a huge increase over the 43-tonne limit of the Il-76. The C-17 has since proved its worth in exercises as well as in humanitarian assistance and disaster relief (HADR) missions like the evacuation of stranded Indian nationals from Yemen in April 2015 and the relief operations following the earthquake in Nepal the same month. Although the C-17 is over 20 years old, the IAF would have dearly liked to exercise its contractual option to acquire another six of what is currently the world’s best strategic airlift aircraft. However, while the mandarins in the Defence Ministry were taking their time to ‘consider the matter,’ as is their wont, C-17 production ceased last year.

In contrast, the C-130J acquisition was far better managed. In 2008, a $962-million contract was signed with the US Government to purchase six C-130J tactical transport aircraft, the world’s most widely used military transporter. The IAF acquired the C-130J-30 version, customised for Special Operations and though the IAF can conceivably use them for regular transport tasks, it would be at the cost of their primary role. Since the IAF was favourably impressed by these aircraft (notwithstanding the accidental loss of one plane in March 2014) a $1.01-billion deal was signed in December 2013 for the purchase of another six with delivery beginning in 2017.

The mainstay of the IAF’s strategic-lift fleet since 1985 was the Il-76MD. However, its serviceability had plunged due to lack of spares. In October 2015, the Defence Acquisition Council (DAC) sanctioned the upgrade of 17 Il-76 aircraft, three Phalcon Il-76 airborne warning and control system (AWACS) aircraft and six Il-78 tanker aircraft at a total cost of Rs. 4,250 crore. Although the precise contours of the upgrade remain unclear, it is likely to include new engines and advanced avionics to extend their service life up to 2035.

What then? Most likely, the IAF would find its heavy-lift fleet inadequate for its manifold responsibilities and rue the missed opportunity to purchase six additional C-17s under the option clause. It would become necessary to induct yet another strategic transport aircraft to replace the Il-76MD.

THE C-295 ASSEMBLY LINE IS EXPECTED BE SET UP IN HYDERABAD WHERE TASL ALREADY HAS FACILITIES

The more advanced Il-76MD-90A that entered service with the Russian Air Force in 2015 might be a logical choice. However, the IAF would need to take a critical look at the state of the Russian aviation industry that has been lamentably unable to meet its requirements of spares for many years. Another possible option is the Airbus A400M Atlas, a European transport aircraft that entered service in 2013. With a 37-tonne payload capacity it is claimed to be the most versatile airlifter currently available. It can also be used as an aerial tanker. It is powered by four counter-rotating Europrop International (EPI) TP400 turboprop engines. However, the aircraft has yet to prove its operational reliability.

Medium-Lift Matters

While the improvement in the IAF’s strategic capability is remarkable, the bulk of its transport fleet is tactical, mainly 104 remaining medium-lift An-32 turboprops, inducted between 1984 and 1991. Their serviceability had deteriorated considerably, making it difficult for the IAF to meet day-to-day airlift commitments. In 2009, the IAF signed a $400-million contract with Ukraine’s Ukrspetsexport Corporation to upgrade the An-32s to An-32RE standard. The upgrade includes advanced avionics, cockpit modification, noise and vibration reduction, plus enhancement of payload capacity from 6.7 to 7.5 tonnes. Their technical life is also increased to 40 years.

While the first 40 An-32s completed their upgrade in Ukraine in 2015, the balance 64 were to be overhauled within the country at the IAF’s No. 1 Base Repair Depot in Kanpur, with Ukrainian experts assisting the Indian technicians. However, progress on the project has been patchy since it is heavily dependent on a regular supply of Ukrainian components as well as engineers from that war-torn country. Some reports indicate the IAF is trying to rope in an Indian maintenance repair and overhaul provider to undertake the work. If it is completed successfully, the An-32 upgrade should keep these aircraft flying till 2030 and beyond.

From Avro to C-295

Another long-festering issue, seemingly resolved in May 2015, was the approval by the DAC of replacement of the 5.1-tonne payload capacity Avro with a modern tactical transporter, the C-295, to be produced jointly by Airbus Defence & Space and Tata Advanced Systems Ltd (TASL), designated the Indian Production Agency (IPA). This Rs. 12,000-crore project has the potential to be a watershed in the history of the IAF transport fleet and of defence aerospace manufacturing in India. For the first time, the stranglehold of the defence public sector undertakings (DPSUs) has been broken and the private sector will be heavily involved in indigenous transport aircraft production, albeit under the guidance of a foreign manufacturer. This is expected to introduce some much-needed competition for HAL.

Although the initial IAF requirement is only for 56 C-295 turboprops to replace its remaining Avros, the same aircraft can meet some transport and maritime recce needs of the Indian Navy. There’s likely to be demand from the Border Security Force (BSF) and the Central Reserve Police Force (CRPF), which are all keen to expand their airlift capability. The possibility of exports is also open. Lastly, if nothing else comes up by the time the An-32 falls due for replacement, this aircraft is eminently suitable. Therefore, some analysts feel the final figure for C-295 production in India could easily touch 200 aircraft.

The new model C-295 features winglets and uprated Pratt & Whitney Canada PW127 turboprop engines that promise an eight per cent increase in range and a 5.5 per cent fuel saving on a typical mission carrying a 5-tonne payload for 1,100 nautical miles. It is particularly suitable for operations at ‘hot and high’ airfields where payload increase in excess of 1,000 kg may be expected.

THE IAF NEEDS TO TAKE A CRITICAL LOOK AT THE STATE OF THE RUSSIAN AVIATION INDUSTRY THAT HAS FAILED TO MEET ITS REQUIREMENTS OF SPARES

The C-295 assembly line is expected be set up in Hyderabad where TASL already has facilities. One welcome feature of the contract is a performance-based logistics package that should give the IAF a high fleet serviceability. After the contract is signed, the first 16 flyaway aircraft must be delivered within two years. Next will be eight aircraft in semi-knockdown condition and then eight in complete knockdown state. The final 24 aircraft must be manufactured in India.

However, although almost a year has passed since DAC approval, there seems to be little tangible progress. No date has been set for signing the contract, which has a 50 per cent offset clause. With the convoluted procedures of any major defence contract, the longer the delay the more suspicions will grow that all may not be well. There’s still a lengthy process ahead including approval of the IAF’s Technical Evaluation Committee (TEC) report, field evaluation, staff evaluation, technical oversight, commercial negotiations and approval by the Cabinet Committee on Security (CCS). Only then will financial outlays be made and the contract signed.

The Missing Indigenous MTA

The quick and smooth induction of extremely capable American aircraft for the IAF’s transport fleet should not give rise to complacency because the nation needs to have its own manufacturing capability. Unfortunately, attempts to establish a military aerospace industry and break free of the current unhealthy near total dependence on imports have met with scant success. It is to be hoped that the government’s ‘Make in India’ initiative will give a boost to indigenous manufacture of aircraft, not merely licensed-production or assembly. The revised Defence Procurement Procedure (DPP) 2016, now expected in April, has a welcome new Indigenous Design, Development and Manufacturing (IDDM) category under ‘Buy Indian’.

For some time, a joint Indo-Russian project to develop the UAC/HAL II-214 multi-role transport aircraft (MTA) seemed to hold great promise. It was intended to build a new twin turbofan 15/20-tonne tactical airlifter to ultimately replace the An-32 fleet, with $300 million investment from each side. However, serious disagreements over the project may have sounded its death knell. The main bone of contention is the engine. The IAF will need the 45-strong MTA fleet to fly at Himalayan heights and the Aviadvigatel PS-90A76 engine that Ilyushin proposes cannot relight at those heights, thus making it potentially unsafe to operate. The PS-90 also does not have a full authority digital engine control (FADEC) system to control all aspects of engine performance. Another adverse factor is the IAF’s unhappy experience with supply of spares for PS-90 engines which results in low serviceability of its Il-76 fleet. Finally, the An-32 upgrade seems to have strengthened the IAF’s resolve not to lightly accept what appears to be a rather costly platform beset with technical and design issues, since it is expected to remain in service for three decades or more.

One viable alternative would be to increase the C-295 order. The production of 56 C-295s to replace the Avro must be completed within ten years after contract signing. This would be close to the An-32 withdrawal from service period. The C-295’s payload capacity of 9.25 tonnes is comparable to the An-32RE’s 7.5-tonne capacity, making the C-295 suitable for An-32 replacement. Such a decision would also have the advantage of meeting ‘Make in India’ requirements while simultaneously reducing the number of transport aircraft types operated by the IAF.