INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

Next Gen Aero Engines

The development of aircraft engines, the most crucial and expensive component, will drive the airline industry’s green transition, with options ranging from conventional upgrades to innovative designs like open fans, hybrid-electric systems, and hydrogen-burning engines

The next generation of aero engines is set to revolutionise aviation, heralding an era of unprecedented efficiency, reduced emissions, and enhanced performance across both commercial and military sectors. These advanced engines are at the forefront of propulsion technology, promising a cleaner and more sustainable future for air travel. As we delve into the specific technologies and leading products driving this innovation, it becomes evident that the future of flight is being reshaped by these groundbreaking developments.

Central to the design of future civil aerospace engines is a focus on efficiency, which directly impacts fuel consumption, operating costs, and environmental sustainability. Leading engine manufacturers are unveiling new technologies aimed at burning less fuel, reducing CO2 emissions, and minimising noise. In addition to enhancing engine efficiencies, there is significant exploration into electric and hybrid propulsion systems. With the rise of drones and Urban Air Mobility (UAM) vehicles over populated areas, the aero-acoustics of these engines are also becoming a crucial design consideration. Advances in propulsion technology are poised to shorten engine development cycles, reduce weight, enhance performance, lower fuel consumption, increase reliability, and extend component life, all while reducing emissions and maintenance requirements. The four leading engine manufacturers are taking diverse approaches as they develop new models, each contributing to the transformative landscape of aero engine technology.

CFM INTERNATIONAL

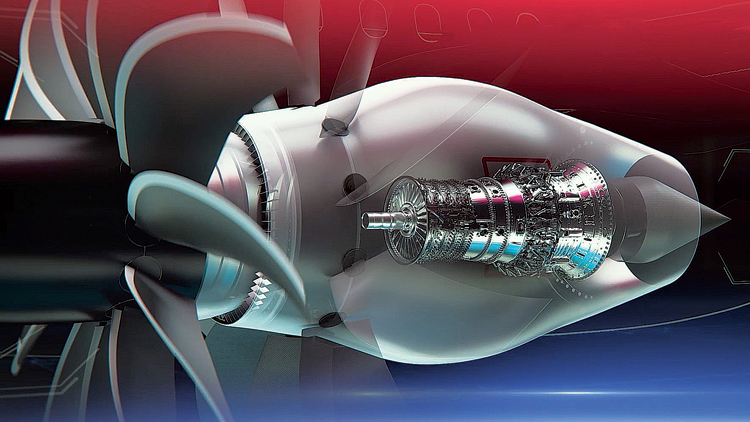

CFM International, a joint venture between GE Aviation and Safran, were behind the best-selling aircraft engine of all time, the CFM56, and now the high-bypass turbofan LEAP (Leading Edge Aviation Propulsion) engine. LEAP has been flying with components from Ceramic matrix composites (CMC) and has 3D-printed fuel nozzles. CFM has already announced their potential successor which is being hyped as “the future of flight”. The CFM new RISE (Revolutionary Innovation for Sustainable Engines) programme will produce the next-generation CFM engine by the mid-2030s. The programme targets are to reduce fuel consumption and carbon emissions by more than 20 per cent while also being 100 per cent compatible with both Sustainable Aviation Fuel (SAF) and hydrogen. The RISE programme would be the first of its kind open-fan architecture that will yield the greatest benefit. It will help optimise engine operation across each segment of flight.

PRATT & WHITNEY

Pratt & Whitney is best known for the six variants that collectively form the GTF family. The GTF engine fans rotate much slower than the compressor and turbine, which gives them a 12:1 bypass ratio, which is the highest in the industry. The geared turbofan design results in “double-digit reductions in fuel efficiency, noise and emissions”. Pratt & Whitney views the GTF’s new designs with even higher bypass ratios as “the architecture of the future”. The new GTF Advantage engine will be the most environmentally friendly option capable of even lower lifecycle emissions with sustainable aviation fuel (SAF). Successfully tested on 100 per cent SAF, GTF Advantage engines will be available soon.

Pratt & Whitney is also working on a hybrid-electric turboprop demonstrator on the De Havilland Canada’s Dash 8-100. It is expected to begin flight tests in 2024. The regional market’s will be the first to benefit from the lower-carbon technologies like all-electric, hybrid-electric and hydrogen-powered propulsion. The same will later percolate to larger aircraft. Also, advancements in turboprop technology could lead to a resurgence in this fuel-efficient design for regional aircraft. Turboprop engines use a propeller driven by a turbine engine, offering significantly lower fuel consumption compared to turbofans.

GE AVIATION

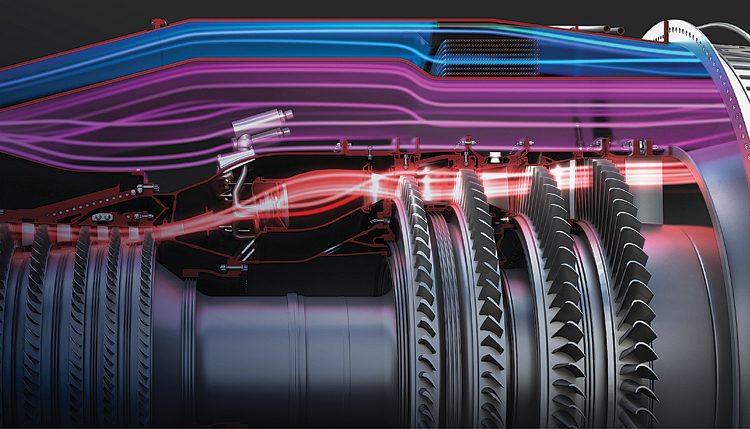

GE Aviation had its large turbofan GE90 engine that introduced the composite fan blades. The engine was also the first to use FAA-approved 3-D printed parts. The GE90 and newer technologies were ported to the GEnx, which is around 15 per cent more fuel-efficient. The GE9X is GE’s latest engine and has the world record for the highest thrust, at 1,34,300 pounds. The reduced fan blade thickness improves aerodynamic efficiency, while its lower fan-radius-ratio maximises air-flow and minimises drag. Combined with fewer fan blades than many others, GE9X boasts the most efficient fan that increases performance and decreases fuel burn. GE9X incorporates more than 65 CMC components, the most of any commercial aircraft engine to date. These CMC components weigh a third of conventional parts, and yet are twice as strong for greater durability. Leveraging additive manufacturing, GE9X combined more than 300 engine parts into just seven 3D printed components, resulting in less weight.

GE is also working on the MESTANG (More Electric Systems and Technologies for Aircraft in the Next Generation) technology. These other technologies include composite fan blades, heat resistant light metal alloys, advanced cooling methods and additive manufacturing.

ROLLS-ROYCE

Rolls-Royce has been famous for its high-bypass Trent turbofans that power many large airliners. Their forthcoming engines feature new architectures and innovative technological improvements to deliver 2-shaft and 3-shaft engine solutions for future aircraft applications. Rolls-Royce is working on building world’s largest jet engine. Called the UltraFan demonstrator, the engine has the largest fan diameter ever of 140 inches. Its power gearbox has reached 87,000 horsepower, which is a new record. In the long run, the engine will have the potential to power very wide body jets.

PROPULSION TECHNOLOGY NEW APPROACH

The new engine technologies will involve engine-airframe integration, new and improved materials and material-processing techniques, advances in turbo-machine technology, progress in combustion technology and vastly improved utilisation of Computational Fluid Dynamics (CFD) in engine design procedures. The carbon-fibre blades allowed high-bypass jet engines that allowed developing efficient long-haul jets that could use just two engines rather than four. Novel technologies such as “smart engines” and the use of magnetic bearings will change the course of engine development. Additive manufacturing offers lighter, cheaper and quick-to-manufacture parts which will cut assembly costs and time, simplify maintenance and save on fuel.

GREENER ENGINE APPROACH

The future of aviation is likely to involve a shift towards cleaner fuels. Increased use of Sustainable Aviation Fuel (SAF) and even hydrogen are being explored to reduce the industry’s environmental footprint. SAF is a biofuel derived from renewable sources like plant oils or waste feedstocks and can significantly reduce lifecycle carbon emissions compared to traditional jet fuel. Recently, Rolls-Royce publicly confirmed that it has successfully completed compatibility testing of 100 per cent Sustainable Aviation Fuel (SAF) on all its in-production civil aero engine types. This demonstrates that there are no engine technology barriers to the use of 100 per cent SAF and that the use of it does not affect engine performance.

Hydrogen, while still in early development for aviation use, holds immense promise as a clean-burning fuel that produces only water vapor as a byproduct. Challenges include onboard storage and infrastructure development, but companies like Airbus are already conducting research flights using hydrogenpowered engines.

Cutting emissions and noise abatement has been possible through technological innovations. Newer models of the mostwidely used aircraft today not only carry more passengers, but also burn 23 per cent less fuel, through much better fuel burn efficiency. Lightweight low pressure turbofans using composite fan blades, high efficiency low pressure turbine, 3D-printed components, hybrid-electric systems, advanced heat-transfer circuits are other breakthrough technologies.

ELECTRIC AND HYBRID-ELECTRIC ENGINES

There is intense activity in the field of battery-driven electric aircraft. However, range is a huge limitation. One litre of lithium-ion battery pack stores 20 times less energy than one litre of jet fuel. Also, unlike jet fuel, the battery weight stays constant throughout the flight. Hybrid-electric aircraft are probably a more practical solution as they can achieve the best of both worlds. In a hybrid-electric configuration, the aircraft uses a combination of energy sources – jet fuel and electricity – either in tandem or alternately. This can optimise the overall energy efficiency and reduce fuel consumption.

GE has teamed up with NASA to test a megawatt-class, multi-kilovolt hybrid-electric propulsion system in simulated high-altitude conditions (up to 45,000 feet). The company will continue testing the system as part of NASA’s Electrified Powertrain Flight Demonstration (EPFD) project. Under a European Union-funded project, the Sustainable Water-Injecting Turbofan Comprising Hybrid-Electrics (SWITCH), several agencies have got together to progress two key technologies – hybrid-electric and water-enhanced turbofan. They will use a Pratt & Whitney GTF engine and work towards combining the technologies for short and medium range aircraft. The Water-Injecting Turbofan (WET) uses residual heat from exhaust gasses to vaporize water and inject it into the combustor. As an integrated system of hybrid electric and WET technologies, SWITCH could achieve up to 25 per cent improvement in fuel efficiency, and sharply reduce CO2 emissions compared to today’s best engines. It will also enable an 80 per cent reduction in NOx emissions and significantly reduced contrail generation.

HEAT RECOVERY CONCEPT

Two new engine concepts under investigation include the ‘Combined Brayton Cycle Aero Engine’ and ‘Multi-Fuel Hybrid Engine’. Currently, over 50 per cent of the energy gets ejected as waste heat. A heat exchanger integrated in a turbofan core can convert recovered heat into useful power which can be used for on-board systems or to power an electrically driven fan to produce auxiliary thrust. A dual combustion chamber, wherein the high temperature generated in the first stage, allows ignition-less combustion in the inter stage, thus reducing CO and NOx emissions. Cryogenic bleed air cooling can enhance the engine’s thermodynamic efficiency.

OTHER NEW INNOVATIONS

The US Department of Defense’s Adaptive Versatile Engine Technology (a) and Adaptive Engine Technology Development (AETD) programmes, and the GE Adaptive Cycle Engine (ACE) are areas of action. Unlike traditional fixed airflow engines, the variable cycle engines automatically alternate between a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings. Incorporating heat-resistant materials and additive manufactured components in the Pulse Detonation Engine (PDE), gives it the potential to radically increase thermal efficiency. These adaptive features also have additional stream of cooling air to improve fuel efficiency and dissipate aircraft heat load. Such engines will increase aircraft engine thrust by up to 20 per cent, improve fuel consumption by 25 per cent and extend range by more than 30 per cent.

CONCLUSION

New technologies will bring change, challenge and opportunity. Developing next-generation aero engines is a complex endeavour, involving the need to balance efficiency and noise, ensure reliability and safety, and manage high development costs. Increased efficiency is crucial, but reducing noise from next-gen engines, especially in urban areas, remains a significant concern, with open-fan architectures presenting specific noise challenges that need addressing. Rigorous testing and certification are necessary to ensure the highest levels of reliability and safety for passengers and crew. The research and development required for these advanced engines can be expensive, necessitating collaboration and investment from governments, airlines, and engine manufacturers. Despite these challenges, the potential benefits of next-generation aero engines are undeniable, promising to propel the aviation industry towards a more sustainable future with cleaner skies, reduced fuel consumption, and improved performance. These advancements will revolutionize air travel and play a crucial role in mitigating the environmental impact of aviation, leading to a future where air travel is faster, more efficient, cleaner, and more sustainable.