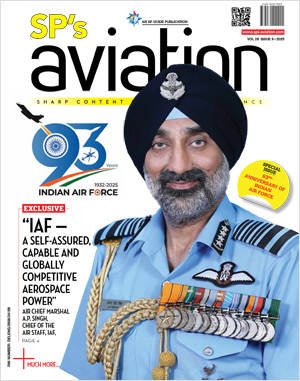

INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

OEMS - ‘Green Sky’ thinking

Dassault is playing a big role in international programmes aimed at enhancing the economy and environmental friendliness of aircraft of the future

Falcon business jets are recognised throughout the industry for their superior performance and handling quality. What is perhaps less well known is that they are also widely considered to be the most economical and environment-friendly executive aircraft in their class.

This reputation is rooted first and foremost in the advanced design of the Falcon line, derived from Dassault’s combat aircraft heritage. The external shape and profile of Falcon wings are engineered to reduce drag while structures and systems are built to be as lightweight as possible, boosting flying efficiency and cutting down on fuel burn. This obsession with efficiency is reflected in the Falcon design approach itself, which seeks to minimise the overall aircraft size without compromising on passenger comfort.

Fuel consumption levels are typically 20 to 50 per cent better than those of competing aircraft for equivalent performance and agility.

But to further enhance the economy and environmental footprint of the Falcon line, and ensure that new models are always one step ahead of increasingly strict regulatory requirements, Dassault also invests heavily in continuous weight reduction and fuel-saving improvements. Currently, about 15 per cent of the company’s manufacturing budget is being spent on such enhancements, despite the softness in the business jet market. In fact, this year, research and development spending will be higher than ever.

One thrust of this effort is aimed at developing green products for new aircraft models. An example is the new Falcon 2000S, which features a PW308C engine with a redesigned Talon II combustor that combined with optimised winglets, allows the aircraft to burn 10 per cent less fuel than models 20 per cent smaller. The Talon II also produces 20 per cent fewer NOx emissions than previous generation aircraft without any power penalty and is 40 per cent greener that required by CAEP/6 rules.

A second focus is on reducing the environmental impact of the company’s production processes—a concept engineers call “eco-design.” Since 2005, Dassault has taken more than 700 major actions in this area, reducing consumption of industrial gas and fuel by 30 per cent and water use by 70 per cent, despite an increase in aircraft production.

All Dassault production facilities, including the US completion operation in Little Rock, Arkansas, are now certified ISO 14001, the international standard which demonstrates that an organisation has developed and implemented an effective environmental management system. Additionally, all chemicals used in production have been categorised in a company-wide EMS and database, certified in 2007.

One notable application of the eco-design approach was the introduction of new chromate-free paints featuring a lower concentration of volatile organic compounds (VOCs) at all Dassault plants. Another was the implementation of a new process for unsealed anodising of aluminium alloy components that allows the quantity of residual chromates on aircraft parts to be sharply reduced.

The ultimate objective is to apply eco-design throughout the aircraft life cycle, from the mining of raw materials and production through in-service operation to end of service and recycling.