INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- The layered Air Defence systems that worked superbly, the key element of Operation Sindoor

- Operation Sindoor | Day 2 DGMOs Briefing

- Operation Sindoor: Resolute yet Restrained

- India's Operation Sindoor Sends a Clear Message to Terror and the World – ‘ZERO TOLERANCE’

- Japan and India set forth a defence cooperation consultancy framework, talks on tank and jet engines

Rise of the Next Generation

There’s no dispute about the need for future engines to be far greener than present ones. So what will the next generation of commercial engines look like?

With the danger of anthropogenic global warming leading to irreversible climate change now firmly on the global agenda, commercial aviation is in a sticky situation. The airline industry is hardly a major source of greenhouse gases, producing just 2.5 per cent of global CO2 emissions. But it is undeniably one of the fastest growing sources. In fact, net aviation emissions could more than triple by 2050. That makes commercial aviation a bad guy and puts it under intense pressure to decarbonise. At the October 2021 Annual General Meeting of the International Air Transport Association (IATA), member airlines agreed to commit to net-zero carbon emissions by 2050.

The industry is following a multipronged approach to achieve IATA’s challenging goal. According to Safran CEO Olivier Andries, “The next generation of airplanes must reduce emissions by 90 per cent as compared with the current fleet.” Of this dramatic reduction, 40 per cent is expected to come from new engine and airframe technologies, 40 per cent from the use of Sustainable Aviation Fuels (SAF) and 10 per cent by streamlining air traffic.

A BRIEF HISTORY OF POWER

Reciprocating piston engines were the only means to power aircraft during the first few decades of flight. However, in the 1930s, two technologists working independently developed a new and more powerful type of aeroengine – the turbojet. In Germany, Hans von Ohain produced the HeS.3B engine. And on August 27, 1939, it resulted in the world’s first successful turbojet-powered flight by the Heinkel He 178. In Great Britain, it was Frank Whittle who invented the gas-turbine engine that powered the first British jet, the Gloster E.28/39, which first flew on May 15, 1941.

Early turbojets were inferior to piston engines since they produced too little power and consumed too much fuel. However, their performance rapidly improved and the first flight of the de Havilland DH.106 Comet – the world’s first commercial jet aircraft – took place on July 27, 1949. Turbojets were succeeded by turboprops and turbofans. The first turboprop airliner to enter service was the Vickers Type 701 Viscount on April 18, 1953, powered by Rolls-Royce Dart 510 engines. The transition from fuel-guzzling turbojets to fuel-efficient turbofans happened gradually. The Rolls-Royce RB.80 Conway low-bypass turbofan was the first to enter service in the late 1950s, without making a splash. Today every large airliner is turbofan powered.

In a turbofan, additional thrust comes by forcing air to pass around the main engine core rather than through it. This air has already been accelerated by the inlet fan and provides thrust without much increase in fuel consumption. Additionally, it cools the engine and helps reduce engine noise. The bypass ratio of a turbofan engine is the ratio between the mass flow rate of the bypass stream and the mass flow rate entering the core. It also describes the relationship between the thrust the fan generates and the energy required to drive the fan. Modern airliner engines have bypass ratios as high as 12:1. That pales in comparison with what the next generation promises.

REMARKABLE RISE

In 1971, Safran Aircraft Engines of France and GE Aviation of the United States formed a 50/50 partnership named CFM International (CFMI) to develop a new turbofan engine in the 20,000 pound thrust class. The resulting CFM56 engine went on to power more than 550 commercial and military types of aircraft worldwide. In 2008, this iconic engine was succeeded by the LEAP engine intended to power new narrow-body airliners. LEAP introduced several new technologies, including carbon-fibre front fan blades and the first Ceramic Matrix Composite (CMC) components in the hot section of the engine. CFM has cut the fuel consumption of its engines, and therefore the CO2 emissions, by 40 per cent over the past 40 years. Next major leap forward – RISE.

The RISE open rotor configuration could dramatically increase fuel efficiency, mainly thanks to its eyepopping bypass ratio of 75:1. Recall that the CFM engines of the early 1980s had a bypass ratio of just 5:1.

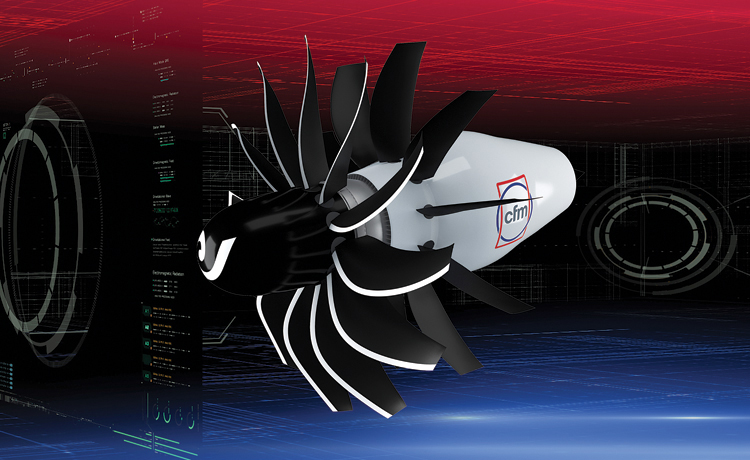

The CFM International RISE (Revolutionary Innovation for Sustainable Engines) Technology Demonstration Program, launched on June 14, 2021, aims to produce a dramatically new generation gas-turbine engine design by around 2035. It will have an open rotor or fan, also called an unducted fan, because it will be without the conventional pod around the rotating fan blades. The blades will be of woven carbon composites, and perhaps as large as 156 inches in diameter, thus sweeping backward a far greater volume of air than present engines.

OPEN TO OPEN ROTOR TECHNOLOGY

Open rotor designs have been tried before, but did not succeed, partly because of excessive cabin noise compared to conventional turbofans. Relatively low aviation fuel prices also meant there was no incentive to risk the huge amounts needed to develop a radically new engine. However, the time is ripe to pursue the open rotor option. For one thing, green pressures have trumped purely economic considerations. For another, the technology now exists to overcome most of the known pitfalls of the design, including noise. The RISE open rotor configuration could dramatically increase fuel efficiency, mainly thanks to its eye-popping bypass ratio of 75:1. To view this figure in perspective, recall that the CFM engines of the early 1980s had a bypass ratio of just 5:1. Thermal efficiency will also be increased by shrinking the engine core, which would increase its already high temperature by as much as 90 degrees Celsius or more. Only CMCs are capable of withstanding such heat. Other innovative cooling methods will also be incorporated.

A major factor behind the confidence of technologists that they can overcome the many hurdles on the path towards the next-generation engine is the rise of CMCs. CMCs consist of ceramic fibres embedded in a ceramic matrix and are a subgroup of composite materials as well as of ceramics. They may withstand temperatures of up to 1,300 degrees Celsius, beyond the melting point of many advanced metallic superalloys. They also offer significant weight advantages, being only one-third the weight of steel. Remarkably, the carbon composite blades on GE Aviation’s GE-90 and GEnx engines have never had an incident of fan blade rupture during their more than 140 million flight hours in service.

That’s not all. Till now every jet engine has invariably burnt kerosene or Aviation Turbine Fuel (ATF). Even if CFM’s new baby uses the same fuel it will still reduce fuel consumption by at least 20 per cent. But it is the flexibility of what this next-generation engine is projected to burn to produce power that makes it so exciting. Additional technologies will make it compatible with 100 per cent SAF (current engines can run with only 50 per cent blends of SAF). It will be capable of hybrid-electric operation, in which part of the thrust is provided by electrical power. It will also be easily adaptable to run on hydrogen, the ‘holy grail’ of engine designers. According to GE Aviation CEO John Slattery, replacing kerosene completely with SAF would reduce CO2 emissions by 80 per cent. And if hydrogen were the fuel it would reduce CO2 emissions by 100 per cent.

THE BEST OF THE REST

Apart from CFMI’s RISE, GE Aviation, Pratt & Whitney and Rolls-Royce are all working independently or in collaboration to substantially reduce aviation emissions. Pratt & Whitney’s Geared Turbo Fan (GTF) technology is relatively new and therefore has scope for further refinement and enhanced fuel efficiency. GE Aviation’s upcoming GE9X is the most fuel-efficient turbofan it has ever produced. Rolls-Royce’s UltraFan, expected to enter commercial service around 2030, will be the largest engine in the world with a fan diameter of 140 inches, and one of the most economical. But these engines represent only incremental improvement, not a distinctly new generation.

Rolls-Royce’s UltraFan, expected to enter commercial service around 2030, will be the largest engine in the world with a fan diameter of 140 inches, and one of the most economical

What unconventional shape might the next generation take? Electrical power is already finding growing utility in small aircraft for short distances. However, for larger planes and longer distance, batteries are too heavy and cannot store enough energy. Hydrogen would surmount this problem, but the energy density of liquid hydrogen is just one fourth that of jet fuel, so it will need much larger storage tanks. Also it is rather doubtful if hydrogen can be produced at the required scale and price to power the bulk of the airline industry without itself leaving a large carbon footprint. All things considered, the RISE open rotor design probably offers the brightest hope of a truly “next generation” commercial aircraft engine.