INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

Future of Flight — Powered by GE

With the threat of catastrophic climate change looming large, commercial aviation simply cannot continue on its present unsustainable trajectory. GE Aviation has therefore embarked on a comprehensive technology-based endeavour to slash aviation’s carbon emissions and rewrite the narrative.

A new refrain is animating General Electric these days: the “Future of Flight”. Were it to come from another enterprise it might sound clichéd. But not when it is GE Aviation, a subsidiary of General Electric, and maker of some of the world’s bestselling military and commercial engines. The history of General Electric, headquartered in Cincinnati, Ohio, goes back all of 105 years to 1917 – just 14 years after powered flight began.

The sweep of GE’s technology development roadmap under the “Future of Flight” is remarkably wide-ranging and momentous. It is part of what US Energy Secretary Jennifer Granholm calls an “all-in effort” to decarbonise aviation, which currently accounts for approximately 2.5 per cent of global carbon emissions – a figure that seems set to rise.

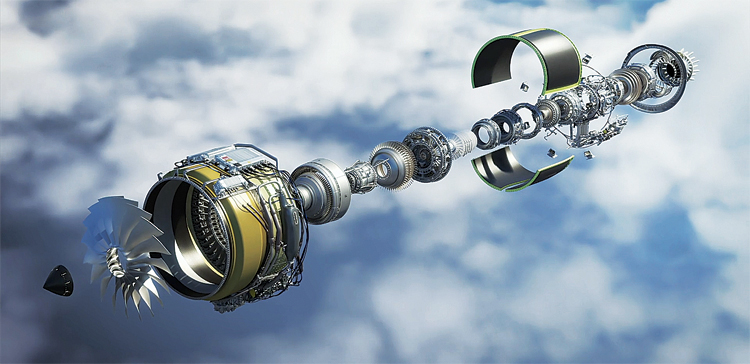

As a measure of General Electric’s determination to put aviation first, it announced a year ago that it would spin off its healthcare and energy businesses and make GE Aviation its main focus. GE Aviation will be rebranded as GE Aerospace by early 2024 to better reflect the new priorities. GE already fields 37,700 commercial aircraft engines and 26,500 military aircraft engines. However, the present campaign does not directly involve its military portfolio. GE’s commercial engines include the GE90, GE9X, GP7-200, CF-6 and GEnx. In addition, CFM International (CFMI), a 50-50 joint company between GE and Safran Aircraft Engines, manufactures the CFM56, the world’s bestselling turbofan, and its successor, the LEAP engine. So, what does GE think is the future of flight? In a word, it is ‘Sustainability’.

SEEKING SUSTAINABILITY

GE’s upcoming GE9X turbofan is the most fuel-efficient engine in its class. Over the coming years, GE also intends to demonstrate some key technologies and advanced engine architecture such as open fan and hybrid-electric propulsion systems, as well as new compact engine cores. It will also actively support the use of alternative fuels, such as Sustainable Aviation Fuel (SAF) and hydrogen, and harness digital technologies to help make the industry more sustainable.

Since June 2021, GE has focussed on the next generation of engines and has launched three key demonstration programmes. First off the blocks was CFM’s RISE (Revolutionary Innovation for Sustainable Engines) Technology Demonstration Program, with its open fan configuration. Second, a partnership with the National Aeronautics and Space Administration (NASA) to develop a megawatt-class hybrid-electric propulsion system. Third, and most crucially, a partnership between Airbus and CFMI to conduct flight tests of a hydrogen-powered engine. Hydrogen is the only path to a true zero-emission aircraft and the genuine sustainability of aviation.

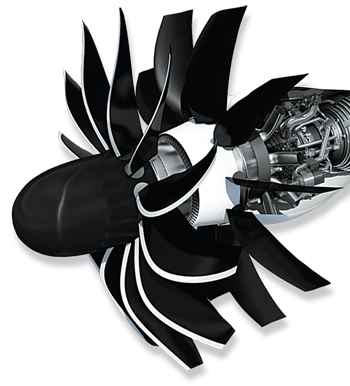

RISE RISING

Launched on June 14, 2021, RISE aims to produce a dramatically new generation gas-turbine engine design by around 2035. It mainly involves an advanced engine architecture – the open fan. Open fan designs have been tried in the past only to be abandoned. However, the technology now exists to overcome most of the known pitfalls, including noise. CFM RISE aims to achieve at least 20 per cent lower fuel consumption and CO2 emissions compared to today’s most efficient engines. Central to the programme is state-of-the-art propulsive efficiency. CFMI intends to make the new engine compatible with 100 per cent SAF and capable of hybrid-electric operation. And with hydrogen being increasingly seen as the “fuel of the future” RISE will be adaptable to run on hydrogen.

CORE ISSUE

One of several enabling technologies included in RISE is a compact engine core. Shrinking the core increases the bypass ratio. Therefore, the engine generates more thrust for roughly the same fuel burn, making it more efficient. GE, in association with NASA, is in the process of testing and maturing new compact core designs, including compressor, combustor and high-pressure turbine to improve thermal efficiency. Ceramic Matrix Composites, an advanced, heatresistant material, is a key part of this effort to improve efficiency and reduce emissions.

ELECTRIFIED POWERTRAIN

In GE’s partnership with NASA to mature a megawatt class hybrid-electric powertrain, the testbed will be a Saab 340B commuter plane powered by two GE CT7-9B turboprop engines. Boeing and BAE Systems are other partners in this effort to demonstrate flight readiness for single-aisle aircraft powered by a hybrid-electric system.

Although hydrogen poses huge challenges at every stage of production, storage and use, it offers the only realistic hope of making aviation emission free

Working with high voltages at high altitudes is extremely challenging because the rarefied air provides very little insulation. So additional insulation and more space between wires is essential to prevent arcing. At the Farnborough International Airshow in June 2022, GE and NASA jointly announced that they have become the first to successfully test high-power, high-voltage hybrid-electric engine components in conditions simulating altitudes up to 45,000 feet. Another problem is that weight reduction, a relentless quest of aircraft designers, is more difficult for an electrical system. Also the amount of energy that can be stored in airborne batteries is low, given the severe weight and space constraints of aircraft.

SIMPLY SAF

The International Air Transport Association (IATA) has set an ambitious target of making the airline industry “net zero” by 2050. Considering that annual worldwide airline passenger numbers are expected to double by 2050, this is a daunting proposition. The use of cleaner fuels is a key component of the strategy to reach the objective. Last year, the US government set two national SAF goals: annual production of three billion gallons by 2030 (a 600-fold increase from 2021) and 35 billion gallons by 2050. This would suffice to meet the entire projected US demand for aviation, and help dramatically reduce emissions associated with air travel in the world’s largest aviation market.

On December 1, 2021, a United Airlines Boeing 737 MAX 8 jet became the world’s first passenger flight to use 100 per cent SAF in one of its two CFM LEAP-1B engines. This was an important step in efforts to increase SAF use. Currently SAF is approved for aviation as a blend of normal Jet A or Jet A-1 fuel, and SAF with a maximum limit of 50 per cent. All GE and CFMI engines can operate with SAF which significantly lowers lifecycle carbon emissions compared to fossil fuels. Being “drop-in”, SAF can be used interchangeably with conventional fuel without modification to engines and airframes.

HOPES REST ON HYDROGEN

Hydrogen is not just the most abundant element in the universe but produces no CO2 when burnt. Measures like increased fuel efficiency, SAF and hybrid-electric planes can reduce but not eliminate emissions. Although hydrogen poses huge challenges at every stage of production, storage and use, it offers the only realistic hope of making aviation emission free.

In February 2022, CFMI signed an agreement with Airbus to collaborate on a hydrogen demonstration programme that will take flight around the middle of this decade. The engineers at CFMI are working to modify a GE Passport engine to make it fully compatible with liquid hydrogen fuel. This includes a complete overhaul of its combustor, fuel system and controls system. The modified jet engine will be mounted on the rear top of the fuselage of an Airbus A380, powered by its original four engines. But the experimental configuration will allow the team to test the hydrogen-powered engine’s emissions, including contrails, and monitor them separately. This is in preparation for entry-into-service of a hydrogen-fuelled commercial aircraft by 2035.

SUSTAINABILITY STRATEGIES

With the threat of catastrophic climate change looming large, commercial aviation simply cannot continue on its present unsustainable trajectory. GE Aviation has therefore embarked on a comprehensive technology-based endeavour to slash aviation’s carbon emissions and rewrite the narrative. GE has already proved that even current airliners have immense potential to reduce emissions. In late 2021, an Etihad Airways Boeing 787 flight from London to Abu Dhabi cut its normal carbon emissions by 72 per cent using SAF and employing innovative route planning to avoid creating contrails. The plane was powered by GE’s GEnx engines and used GE Digital’s Fuel Insight software to analyse data and make fuel-saving adjustments within minutes. It had also used GE’s 360 Foam Wash, a cleaning system that helps improve engine performance and reduce fuel consumption by removing dust and dirt from inside the engine. Ultimately, every ounce of effort counts.

Recently, GE Chief Sustainability Officer Roger Martella was asked to describe what the future of flight might look like. In response, he invited his audience to step into his time machine. “If you go to the airport today,” he said, “you can be pretty confident there’s going to be an airplane there with probably two engines on it using jet fuel.” But looking only ten years down the road, “you may have an airplane that’s using SAF, you may have an airplane that’s a hybrid electric, you may have one that has an open fan, you may have one that runs on hydrogen” – all solutions that GE Aviation is working on. If GE’s sustainability efforts bear fruit, the future of flight may be here sooner than we imagine.