INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

Industry - A New Era in Making

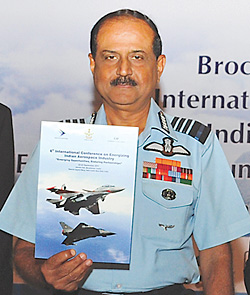

Speaking at the curtainraiser of the Sixth International Conference on Energising Indian Aerospace, Air Chief Marshal N.A.K. Browne cautioned the Indian aerospace industry against over dependence on foreign inputs

Indian aerospa ce stan ds at crossroads, ready to usher in a new era of research and development (R&D), said Chief of the Air Staff Air Chief Marshal N.A.K. Browne. He was speaking at the curtain-raiser function of the Sixth International Conference on Energising Indian Aerospace, held in New Delhi on September 2. A joint effort of the Indian Air Force (IAF), the Centre for Air Power Studies (CAPS) and the Confederation of Indian Industry (CII), the function was attended by senior officers of the IAF, Ministry of Defence (MoD), Defence Research and Development Organisation (DRDO), representatives of Indian and overseas industries, etc.

Describing the event as “a trailer on the shape of things to come in Indian aerospace,” ACM Browne reiterated the key role of the industry in energising Indian aerospace. He, however, cautioned the industry against overdependence on foreign inputs. “For when the time comes, we’ll have to ask our own industry to provide the necessary life cycle support to aircraft and equipment.”

Later, in an interaction with the participants, he talked of the importance of R&D in securing the future of India’s aerospace. Responding to SP’s Editor-in-Chief, Jayant Baranwal, who wondered if R&D in India could be expanded beyond the DRDO, ACM Browne said, “While defence industry players in India like L&T and Mahindra have just entered the field, defence public sector undertakings (DPSUs) have a crucial role in helping DRDO augment its programmes. This will help resolve the life cycle support “disconnect” between DRDO and local players. And since funds for R&D are not easily available, it is up to the PSUs to ensure that at least 15 per cent of allocation goes for R&D. This is important if things are to move faster.”

Brushing aside criticism that things move too slowly in India, he said the comparison of India’s efforts to energise its aerospace sector by building a strong R&D base with that of China does not make sense. “Our system of doing R&D is very different from the Chinese way of doing things,” he quipped. “Here in India, we do make haste, but slowly.” If China’s aerospace industry had developed quickly it is because “they don’t attempt to do everything themselves.” It is not uncommon for the Chinese to borrow technology, rather than spend several years on R&D. “After leapfrogging technology, they set up licence production very quickly as well,” he said. “Their ‘democratic’ system allows this, unlike ours, which is not a party or state-driven effort.” The Chinese are used to exploiting international industrial alliances to leapfrog technological gaps and boosting export revenues from the country’s military industrial complex.

“Today’s modernisation is tomorrow’s readiness,” he said, stressing the need for building infrastructure and capacity to absorb R&D. “The IAF is the most capital-intensive of the three services. So modernising it is not easy,” he said. “But then this is the price we have to pay for national security. We cannot rely on the original equipment manufacturers (OEMs) alone, as a robust industry is imperative for extending logistic and life cycle support for our aircraft and equipment.” He urged all players to consider a ‘cradle-to-grave’ period of at least 40 years. This can be done only with regular exercises like mid-life upgrades, for which OEMs and foreign partners are essential.