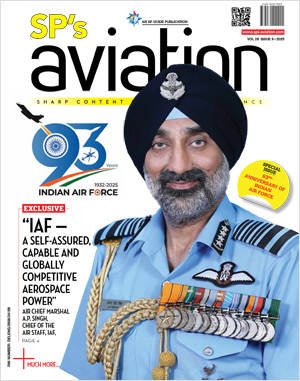

INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

A Mammoth Partnership Powering Aviation World

In April this year, CFM International surpassed 50,000 CFM LEAP and CFM 56 engines sold to over 600 customers around the world

Since its creation in 1974, CFM international, the 50/50 joint-venture between GE Aviation and Safran Aircraft Engines, has been an important player in the commercial aviation industry. CFM, CFM56, LEAP, RISE and the CFM logo are trademarks of CFM International that have taken the company to be among world’s leading suppliers of commercial aircraft engines. 48 years ago Safran Engines and GE Aviation partnered to create CFM, producing the largest fleet of commercial jet engines with innovation and sustainability in mind. In April this year, CFM International surpassed 50,000 CFM LEAP and CFM 56 engines sold to over 600 customers around the world, accumulating over 1 billion engine flight hours.

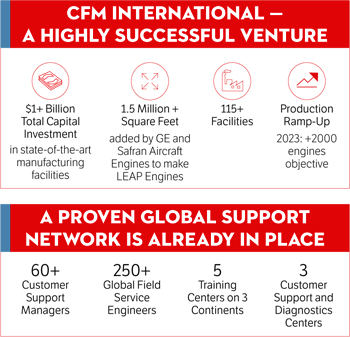

45 years ago in 1977, CFM 56 made its first flight, and ten years after that in 1987, it was the first flight of the Airbus A320 powered by the CFM56 engine. Within a few years, the CFM56-5B became the engine offered on the entire A320 family. CFM has produced and delivered the world’s largest fleet of jet engines in the single-aisle market. To support unprecedented production rate, as CFM parent companies, both GE Aerospace and Safran Aircraft Engines have added new manufacturing capability at sites throughout the US and France, making a combined capital investment of more than $1 billion since 2005.

The advanced CFM LEAP engine continues to set new industry standards for fuel efficiency and asset utilisation, accumulating more than 23 million engine flight hours and 10 million cycles in commercial operation. The fleet is providing 15 to 20 per cent better fuel consumption and lower CO2 emissions, as well as a significant improvement in noise compared to previous generation engines. Since its entry into service in 2016, the LEAP engine allowed operators to save more than 15 million tonnes of CO2 and the LEAP engine has surpassed 20 million flight hours while the LEAP-1A engine alone has logged over 12 million flight hours. On its way to engine certification, CFM pushed its LEAP test programme to the limit. To meet the performance and reliability expectations made to its customers, a total of 60 LEAP engines were built to execute the most extensive ground and flight test certification programme in the company’s history. The LEAP-1A, LEAP-1B and LEAP-1C engine models have all been jointly certified by EASA and FAA.

At the Farnborough International Airshow (FIA) this year, GE announced becoming the first to successfully test high power, high voltage hybrid electric aircraft engine components at simulated altitude conditions. The technology GE is advancing “will help make hybrid electric flight a reality for everyday commercial air travel, and it should have a real and necessary impact on the carbon emissions associated with flying”. Specifically, GE and NASA ran a megawatt-class, multi-kilovolt hybrid electric system in conditions simulating altitudes up to 45,000 feet. Single-aisle planes could account for 70 per cent of the world’s rapidly growing commercial aviation fleet in the near future.

The company underlines, with aviation accounting for about 2.5 per cent of global CO2 emissions, hybrid electric propulsion technologies could help bring the number down. Hybrid electric technology is also compatible with Sustainable Aviation Fuel (SAF) and hydrogen, and with proposed, more efficient engine designs ensuring 15 per cent improvement in fuel consumption and CO2 emissions, compared to CFM56 engines.

CFM: 20 MILESTONES

| 1974Creation of CFM International |

1977First Flight | |

1979First Order | |

1982April 1982: Entry into Service |  |

1984March: First CFM56-powered Boeing 737 | |

1984December: The Ramp-up begins |  |

1987CFM Powers Airbus | |

1991Unprecedented Production | |

1993Boeing Confirms | |

1997First flight of Boeing 737 NG | |

19991000 engines a year | |

2004Higher Performance CFM56 engines | |

200515,000th CFM56 | |

2005CFM LEAP Unveiled | |

2008Partnership extended to 2040 | |

20131,500 engines/year | |

2016Production Peak | |

2017Production Ramp-down begins | |

2018Year of Transition | |

2019Thanks a Billion! |  |

Source: CFM

CFM56 ENGINES

| Aircraft | Engines | Operators | Hours | Cycles | |

|---|---|---|---|---|---|

| CFM56-2A E3/KE3/E6 | 41 | 193 | 4 | 2,907,425 | 1,194, 938 |

| CFM56-2B KC/RC135 | 470 | 1,966 | 5 | 28,740,285 | 8,634,932 |

| CFM56-2C DC8-70 | 110 | 525 | Out of Service | 16,348,980 | 6,927,353 |

| CFM56-3 B737-300/-400/-500 | 1,989 | 4,496 | 297 | 225,881,887 | 159,904,943 |

| CFM56-5A A319ceo/A320ceo | 535 | 1,191 | 50 | 62,939,837 | 36,160,575 |

| CFM56-5B A318ceo/A319ceo/A320ceo/A321ceo/ACJ | 4,188 | 9,091 | 218 | 256,452,633 | 146,170,258 |

| CFM56-5C A340 | 247 | 1,133 | 36 | 74,341,584 | 11,002,791 |

| CFM56-7B B737-600/-700/-800/-900/BBJ | 7,089 | 15,211 | 256 | 469,578, 917 | 242,324,614 |

| Total | 14,669 | 33,806 | 670 | 1,137,191,548 | 612,320,404 |

*as of December 31, 2021,

Source: CFM

LEAP ENGINES

| Aircraft | Engines | Operators | Hours | Cycles | |

|---|---|---|---|---|---|

| LEAP-1A A320neo | 1,113 | 2,443 | 73 | 12,066,405 | 5,941,229 |

| LEAP-1B 737 MAX | 673 | 1,528 | 56 | 3,225,652 | 1,226,776 |

| Total | 1,786 | 3,971 | 127 | 15,292,057 | 7,168,005 |

*as of December 31, 2021,

Source: CFM

4,300 CFM LEAP engines have been delivered to the customers, flying an average of 10 hours a day and up to 11 flight cycles, every day. This has also made way for more uptime and less downtime as well as a higher utilisation of 96 per cent which means more flights & more flexibility to fly when and how you want. Additionally, supporting 25-minute gate turnaround times, which means less time at the gate and more flying. The engine uses 90 miles per gallon per passenger, delivering 20 per cent fuel efficiency, flying with LEAP uses 66 per cent less fuel. It also opens up new routes, supporting longer flight legs, enabling flight options of eight hours or more. The engine is 3-D woven and has also proven to be aerodynamically efficient. The LEAP engine’s fan blades are manufactured from 3-D woven RTM (Resin Transfer Molding) carbon fiber composites, an industry first for CFM. This technology results in fan blades that are not only lightweight but so durable that each individual blade is strong enough to support the weight of a wide-body airplane like the Airbus A350 or Boeing 787. The LEAP engine is the first engine to use additive manufacturing to “grow” complex, fully dense yet lighter engines. Its fuel nozzles are 25 per cent lighter than previous models and five times more durable than parts manufactured conventionally.

The LEAP engine features the second generation twinannular, Premixing Swirler Combustor (TAPS II) that reduces NOx emissions by 50 per cent versus CAEP/6 standards. Unlike traditional combustors that mix fuel and air inside the combustion chamber, the LEAP nozzle pre-mixes these elements to provide what our engineers call lean burn combustion. We just call it revolutionary. The unique LEAP debris rejection system provides the best erosion protection, preventing sand, dirt, and other harmful particles from reaching the engine core. As a result, the highly durable, more efficient LEAP engine stays newer for longer. The LEAP engine started revenue service in August 2016 and as of June 2022, more than 4,000 LEAP engines were in service on six continents, flying in various environments, listing 9,700 LEAP engines on order.

The CFM56 engine was built on over four decades of experience and technological excellence. With more than 33,000 engines delivered to date, it powers more than 600 operators worldwide and has logged more than 1 billion flight hours. The CFM56-5B is the engine of choice for the A320ceo family, having been selected to power nearly 60 per cent of the aircraft ordered. Today, it is the only engine that can power every model of the A320ceo family with one bill of materials. The engine’s broad-based market acceptance has been because of its simple, rugged architecture, which gives it the highest reliability, durability, reparability and the lowest cost of ownership in its class.

The CFM56-7B is the exclusive engine for the Boeing Next-Generation single-aisle airliner. In total, more than 15,000 CFM56-7B engines have been delivered to power 737 aircraft, making it among the most popular engine-aircraft combinations in commercial aviation history. The engine’s broad-based market acceptance is due to its simple, rugged architecture, which gives it the highest reliability, durability, and reparability with the lowest cost of ownership in its class.

Demand for the CFM56 family is still strong. In 2016, the CFM56 programme reached record production rates and the manufacturer is sure that the production will continue until all current aircraft orders are filled. GE Aerospace and Safran Aircraft Engines will also continue to provide spare engines and parts, and comprehensive through-life support during the CFM56’s remaining service lifetime of over 30 years.